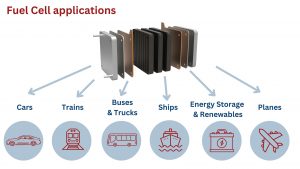

Fuel cells have become a viable eco-friendly power source, and advancements in the technology continue to be made. Today, fuel cells are already used for primary and backup power for commercial, industrial, and residential buildings. However, fuel cells are also used to power a variety of vehicles, including forklifts, cars, buses, boats, motorcycles, and submarines. As fuel cell technology improves, the importance of using high-purity graphite in fuel cells’ bipolar plates, gas diffusion layers, and catalysts is becoming increasingly evident.

As the electric vehicle (EV) industry grows, driving range has proven to be a major challenge. Fuel cells can be used in both stationary and mobile applications, although the latter requires access to a refuelling station. However, standard electric vehicles are still much more limited by their batteries. This is not very practical in many commercial applications where vehicles cover vast distances, or in countries which are less densely populated and have long driving distances. Fuel cells can deliver electrical power at driving ranges comparable to gas or diesel engines. Therefore, fuel cells are frequently used in mass transportation/buses, for example in China and North America, particularly in fleet-type applications where vehicles return to a central point each day. Fuel cell buses operate in a number of US states, and also in the UK.

Increasingly, car manufacturers are looking at this technology on a larger scale. Daimler and Honda are already leasing fuel cell vehicles and are being followed by other car makers like Toyota and Hyundai.

A fuel cell is an electrochemical device that converts the chemical energy from a fuel into electricity through an electrochemical reaction of the hydrogen-containing fuel with the air oxygen or another oxidising agent. Bipolar plates (BPs) are a key component of fuel cells with multifunctional character: they conduct electrical current from cell to cell, remove heat from the active area, and prevent leakage of gases and coolant. Gas diffusion layers (GDL) are essential in order to uniformly distribute the fuel gas and the oxygen from the air. Catalysts and catalyst substrates are decisive in order to increase the rate of the fuel cell electrochemical reactions.

Graphite in fuel cells is used as a conductive material for the bipolar plates, which are an essential component of the fuel cell structure. Super thin graphite bipolar plates must be pure and of high quality to improve electrical and thermal conductivity, as well as ensure long-life operation.

The bipolar plates in proton-exchange membrane fuel cells, one of the most popular technologies, require large flake, high-purity graphite. Fine grained graphite is also used as additives and fillers, but this is a relatively small component of fuel cells.

Graphite is used also in GDL, where graphite is impacting the porosity of this layer.

Finally, high-purity graphite is used as catalyst substrate, enabling the precious catalyst metals to be in close contact with the reactant chemicals, while avoiding any contamination.

Fuel cells rely on an electrochemical process and not on a combustion, noxious emissions from fuel cells are really non-existent – an absolute gamechanger even compared to the cleanest fuel combustion processes. Water and heat are the only by-products from fuel cells. Fuel cells are also much more efficient than combustion engines in converting fuel to energy. As they have no moving parts, fuel cells are quiet, durable, reliable, and long lasting with little maintenance.

The EU is actively pursuing international co-operation on renewable hydrogen research and innovation through Mission Innovation, a global initiative to accelerate efforts in renewable energy innovation. The goal of the Clean Hydrogen Mission is to reduce the costs of clean hydrogen to the end user to $2/kg by 2030, and to develop at least 100 hydrogen valleys worldwide by 2030. National policies in place have been recorded by the International Energy Agency (IEA) report on hydrogen.1

As part of its RePowerEuropePlan strategy,2 in 2020 the European Union adopted a comprehensive Hydrogen Strategy3 consisting of a number of actions: a hydrogen accelerator, a Hydrogen Energy Network, a European Clean Hydrogen Alliance, and a variety of research initiatives. On 8 July this year, the European Commission adopted the EU Strategy for Energy System Integration and Hydrogen.4 The former tackles charging infrastructure and grids, while the Hydrogen Strategy focuses on long-haul and heavy-duty vehicles and hydrogen infrastructure.

For hydrogen infrastructure for transport vehicles, there are different issues around the refuelling infrastructure than private vehicles. For transport fleets, the European Commission believes that hydrogen fuelling stations can “easily be supplied by regional or local electrolysers, but their deployment will need to build on clear analysis of fleet demand and different requirements for light- and heavy-duty vehicles.” Therefore, hydrogen fuel cells should be further encouraged in heavy-duty road vehicles, coaches, special purpose vehicles, and long-haul road freight.

The European Commission also noted that about 46% of the European mainline network is currently still being served by diesel technology and therefore hydrogen fuel cell trains could be developed to other viable train commercial routes that are otherwise difficult or not cost-effective to electrify.

In parallel, the European Clean Hydrogen Alliance5 is holding roundtables focused on trucks/buses, light-duty vehicles, trains, ships, fuel cells, drive trains, tanks, and hydrogen refuelling stations (HRS). Hydrogen policies are now also spread over many European countries, but with large differences. In 2021, 19 out of 34 Member States had a national hydrogen strategy and the geopolitical changes have accelerated discussions and activities.

Following a European Commission’s Joint Research Centre (JRC) report on the global deployment of large-capacity (200 kW or more) stationary fuel cells identifying drivers for and barriers to building a stronger European presence, the Fuel Cell and Hydrogen Observatory (FCHO)6 published its reports in June 2022 on technologies, supply and demand, policies, and standards.7

The European Clean Hydrogen Alliance8 identified a pipeline of over 750 investment projects that its members indicated to undertake by 2030. Projects are located in almost all EU Member States and include the production of hydrogen (projects for the installation of over 50 GW electrolysers), transportation and its usage by industry, mobility applications, energy systems and in buildings.

The Clean Hydrogen Partnership9 under Horizon Europe is raising the research level with an EU support of €1bn for the period 2021-2027, complemented by at least an equivalent amount of private investment (from the private members of the partnership), bringing the total budget to above €2bn.

In its report on hydrogen, the International Energy Agency illustrated that, with the development of patent applications for fuel cells 2010-2019,10 Europe ranks second after Japan.

The EU has a system of identifying Important Projects of Common European Interest (IPCEI). The first IPCEI in this area is called ‘IPCEI Hy2Tech’, which includes 41 projects and was approved in July 2022. It aims at developing innovative technologies for the hydrogen value chain to decarbonise industrial processes and the mobility sector with a focus on end users.

In September 2022, the Commission approved ‘IPCEI Hy2Use’, a second project which complements IPCEI Hy2Tech and which will support the construction of hydrogen-related infrastructure and the development of innovative and more sustainable technologies for the integration of hydrogen into the industrial sectors. This project involves 29 companies and 35 projects from 13 Member States. The Member States will provide up to €5.2bn in public funding, which is expected to unlock an additional €7bn in private investments.

In a joint research project called ‘miniBIP II’,11 the Fraunhofer Institute for Material and Beam Technology IWS Dresden, the German Automotive group Daimler, and the Finnish steel company Outokumpu Nirosta have now developed an economical alternative for a faster and less complex, less costly, and more environmentally sustainable mass production. Instead of using gold in the continuous production of bipolar plates, they coat the plates with a very thin carbon coating. By using physical vapour deposition, an electro car in a vacuum chamber first vaporises the carbon, which is subsequently deposited on the stainless steel in a highly pure, uniform, and very thin layer.

Another project under Horizon Europe is PEMTASTIC, bringing together Imerys, the Deutsches Zentrum für Luft- und Raumfahrt, fuel cell producers and academics, and aiming to meet the key technical challenges to increase durability of membrane electrode assemblies (MEAs) for HD applications. These challenges are approached with a combination of model-based design and the development of a durable CCM using innovative materials tailored for heavy-duty operation at high temperature (105°C). The quantitative targets correspond to a durability of 20,000 hours, maintaining a state-of-the-art power density of 1.2 W/cm2@0.65 V at a Pt loading of 0.30 g/kW.

According to the JRC’s Critical Raw Materials for Strategic Technologies and Sectors in the EU. A Foresight Study12 : “The shift to e-mobility will require batteries, fuel cells and lightweight traction motors not only for cars but also for e-bikes, scooters, and heavy-duty transport. Defence and aerospace have always been strategically important and remain at the forefront of technological developments; they deploy almost all of the technologies.”

Throughout its report, the JRC identifies the need to address the bottlenecks of raw material supplies, including graphite, for these applications.

In the US, it has been estimated that there is more graphite in a fuel cell vehicle than there is in an electric vehicle. The United States Geological Survey stated that: “Fuel cells have the potential to consume as much graphite as all other uses combined.” The global fuel cell market is experiencing rapid growth and is expected to continue to grow at a CAGR of 20.9% through 2025.

Investment in research projects will likely continue, with new developments in fuel cell materials expected in the coming years. The next European Fuel Cell Forum13 will be held on 4-7 July 2023 in Lucerne, Switzerland.

Dr Corina Hebestreit

Secretary General

European Carbon and Graphite Association

http://www.ecga.net/

https://www.linkedin.com/company/ecga-carbon-graphite/?originalSubdomain=be

https://twitter.com/Ecga_C

Please note, this article will also appear in the twelfth edition of our quarterly publication.

Innovation News Network brings you the latest science, research and innovation news from across the fields of digital healthcare, space exploration, e-mobility, biodiversity, aquaculture and much more.

Disclaimer: www.innovationnewsnetwork.com is an independent portal and is not responsible for the content of external sites.

Please Note: Phone calls may be recorded for training and monitoring purposes.